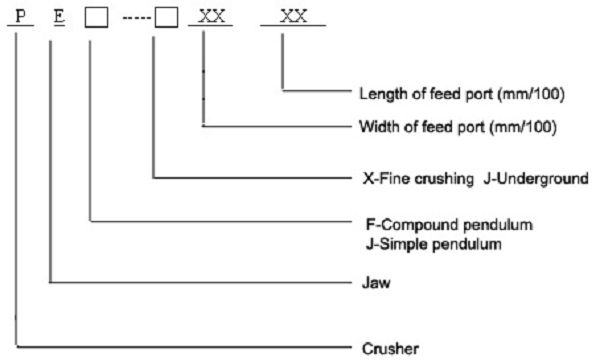

Jaw crusher is one crushing machine with extensive application, and can be classified into PEF compound pendulum jaw crusher and PEJ simple pendulum jaw crusher.

Generally speaking, PEF compound pendulum crusher is suitable for coarse and intermediate crushing of various ores and rocks with compression strength of 250MPa or below, three types of crushers above PEF0609 are able to crush various hard ores and rocks. PEF-X compound pendulum jaw crusher is typically suitable for fine crushing of ores and rocks with intermediate hardness, while simple pendulum jaw crusher is able to crush ores and rocks differently in hardness, and is especially suitable for crushing various hard and strong-corrosive rock materials.

Specifications

Technical Parameters

1 Performance Parameter Table of PEF Compound Pendulum Jaw Crusher

| Specification | PEF | PEF | PEF | PEF | |

Width of | L mm | 250 | 400 | 500 | 600 |

W mm | 400 | 600 | 750 | 900 | |

Recommended maximum | 210 | 340 | 400 | 500 | |

Width of open-side | Nominal size mm | 40 | 60 | 75 | 100 |

Adjustment range mm | ±20 | ±30 | ±27 | ±25 | |

Output if discharge port | 10 | 18 | 40.5 | 60 | |

Motor | Model | Y180L-6 | Y225M-6 | YR280M-6 | JR75-8 |

Power kW | 15 | 30 | 50 | 75 | |

Speed r/min | 970 | 980 | 985 | 730 | |

Voltage V | 380 | ||||

Overall | L mm | 1033 | 1560 | 3495 | 2575 |

W mm | 1016 | 1742 | 1940 | 3723 | |

H mm | 1140 | 1593 | 2205 | 2373 | |

Total weight | 2325 | 6650 | 10570 | 16950 | |

| Specification | PEF | PEF | PEF | PEF | |

Width of | L mm | 750 | 900 | 250 | 250 |

W mm | 1060 | 1200 | 750 | 1050 | |

Recommended maximum | 630 | 750 | 210 | 210 | |

Width of open-side | Nominal size mm | 110 | 130 | 40 | 40 |

Adjustment range mm | ±30 | ±35 | ±20 | ±20 | |

Output if discharge port | 110 | 130 | 20 | 32 | |

Motor | Model | YR280M-6 | JR126-8 | Y225M-6 | Y280S-6 |

Power kW | 90 | 110 | 30 | 45 | |

Speed r/min | 972 | 730 | 980 | 980 | |

Voltage V | 380 | ||||

Overall | L mm | 2730 | 5000 | 1482 | 1482 |

W mm | 2760 | 4471 | 1914 | 2342 | |

H mm | 2820 | 3280 | 1516 | 1535 | |

Total weight | 27940 | 44130 | 6345 | 7715 | |

Remark: Output in table means ores (at natural state) with bulk density of 1.6t/m3 of to-be-crushed materials and compression strength of 150MPa, new jaw plate is contributing to continuous feeding, and granularity of material fits to relevant national standards.

2 Performance Parameter Table of PEJ Simple Pendulum Jaw Crusher

| Specification | PEJ | PEJ | PEJ | PEJ | |

Width of | L mm | 900 | 1200 | 1500 | 2100 |

W mm | 600 | 900 | 1200 | 1500 | |

Recommended maximum | 500 | 750 | 1000 | 1300 | |

Width of open-side | Nominal size mm | 100 | 130 | 155 | 180 |

Adjustment range mm | ±25 | ±35 | ±40 | ±45 | |

Output if discharge port | 60 | 180 | 310 | 550 | |

Motor | Model | YR315M-8 | JR126-8 | YR450-12 | YR500-12 |

Power kW | 75 | 110 | 160 | 250 | |

Speed r/min | 740 | 730 | 492 | 490 | |

Voltage V | 380 | 380 | 3000/6000 | 3000/6000 | |

Thin oil | Model |

|

| Lubrication | Lubrication |

Pressure MPa |

|

| 0.4 | 0.4 | |

Dry oil | Model | JB2305-78 | JB2305-78 | JB2305-78 | JB2305-78 |

Pressure MPa | 10 | 10 | 10 | 10 | |

Remark: Output in table means the bulk density of to-be-crushed materials is 1.6t/m3.

Features of PEF jaw crusher

–Excellence in casting engineering

–Excellent material intake capacity

–Easy installation & maintenance

–High production and reduction

–Reliability, high availability

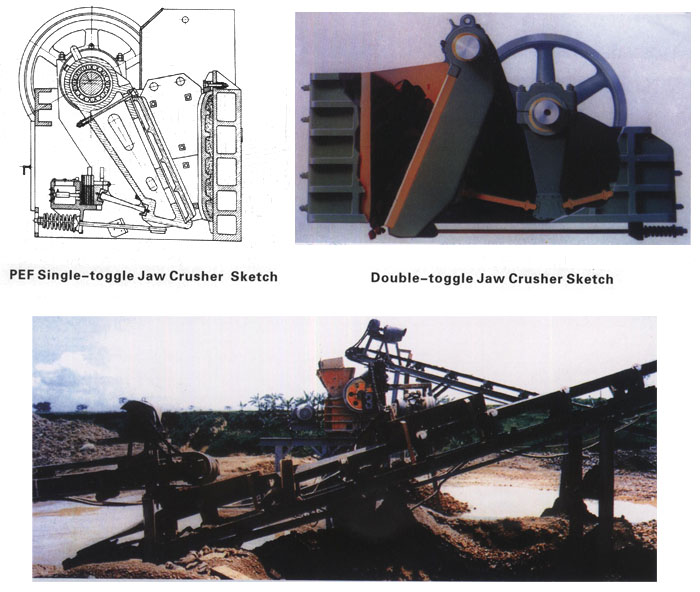

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.