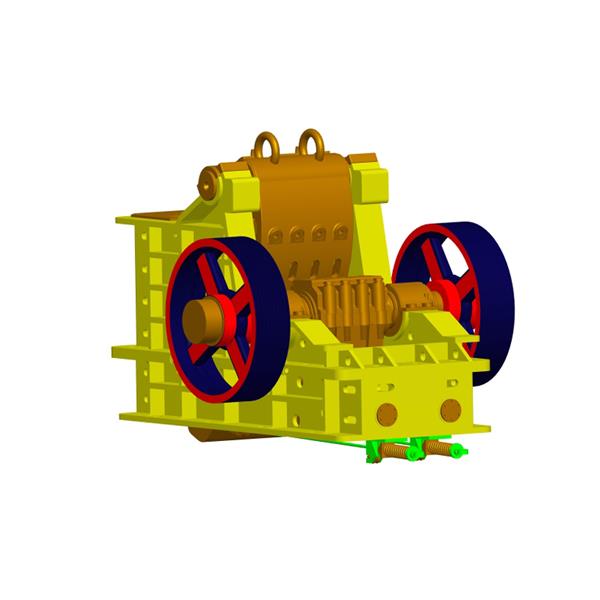

EO PEJ jaw crushers have features of simple structure, reliable performance, easy operation, easy maintenance, safety use, etc.

According to the structure, jaw crusher can be divided into PEF double toggle jaw crusher (single knee plate jaw crusher) and PEJ simple toggle jaw crusher(double knee plates jaw crusher)

Double toggle jaw crusher, mainly consist of the frame body, moving jaw, knee plates and material output adjusting device. Simple toggle jaw crusher, mainly consist of frame body, moving jaw, knee plates, connecting rod and material output adjusting device.

Performance Parameter Table of PEJ jaw crusher

main performance parameters

model | Feeding size mm | Maximum feeding size | Width of opening edge discharge mm | Output when in nominal dimension m3/h | ||

Width B | length | nominal dimension mm | Adjustment range | |||

PEJ 0609 | 600 | 900 | 500 | 100 | ±25 | 60 |

PEJ 0912 | 900 | 1200 | 750 | 130 | ±35 | 180 |

PEJ 1215 | 1200 | 1500 | 1000 | 155 | ±40 | 310 |

PEJ 1521 | 1500 | 2100 | 1300 | 180 | ±45 | 550 |

model | Main motor | thin oil lubrication | Dry lubrication | |||||

model |

kW |

r/min |

V | Model of lubritory |

MPa | Model of grease punm |

MPa | |

PEJ 0609 | YR315M—8 | 75 | 740 | 380 |

|

| JB2305—78 | 10 |

PEJ 0912 | JR126—8 | 110 | 730 | 380 |

|

| JB2305—78 | 10 |

PEJ 1215 | YR450—12 | 160 | 492 | 3000/ | KH934 | 0.4 | JB2305—78 | 10 |

PEJ 1521 | YR500—12 | 250 | 490 | 3000/ | KH934 | 0.4 | JB2305—78 | 10 |

Features of PEJ jaw crusher

1.Excellence in casting engineering

2.Excellent material intake capacity

3.Easy installation & maintenance

4.High production and reduction

5.Reliability, high availability

PEJ jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw, called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap.

EO is one of professional manufacturer for designing, developing, testing and manufacturing of gyratory crusher, which has more than 60 years history. EO has produced more than 8000 sets of jaw crusher, cone crusher and gyratory crusher. PEF、PEJ、PEF-X has been produced in 15 series. EO PEJ jaw crusher equipped many mining companies and metallurgy companies in China. Many products have been draw into international market as early as in the '60 s and won several awards. EO is the presiding company for making the occupation standard Simple toggle jaw crusher JB/T 3264—2002

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.