MTN series horizontal roller mill are newly developed pulverizing equipment suitable for grinding different materials like raw material of cement, clinker, slag cement, steel slag, coal ash, etc. The horizontal roller mill is provided with reliable operation, compact structure and low power consumption integrated from ball mill, vertical mill and roller mill.The MTN series Horizontal Roller Mill manufactured by EO were designed and manufactured in accordance to the laminated grinding principle, by which the materials to be processed will go through the equipment one time with multiple grindings. The equipment has the characteristic of high adaptability to process variety of different materials. When used for processing the same material, the power consumption of is only about 50% of ball mill. The horizontal roller mill has lower attrition and less wear parts without grinding medium. The MTN series horizontal roller mills manufactured by EO are newly developed energy-saving environmental protection pulverizing equipment with advantages of simple system flow, high service factor, flexible process, short-time material conversion between materials, less occupied area, less construction investment, less construction cycle.

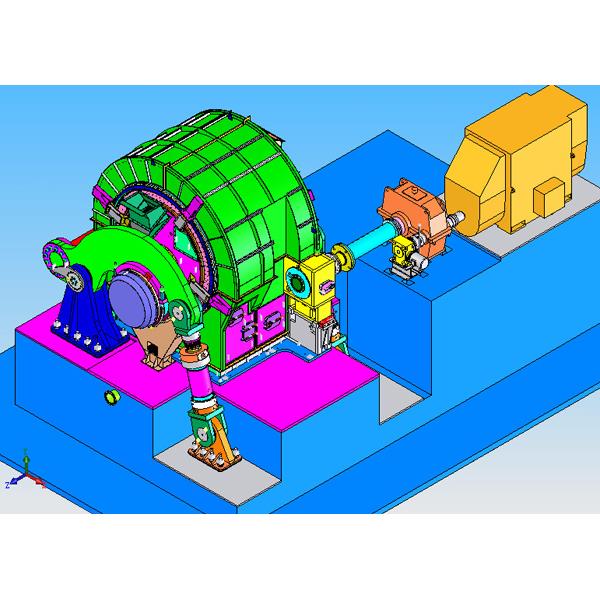

Working principle of MTN horizontal roller mill:

Large materials are crushed by Jaw crusher to the needed sizes firstly, and then the materials are fed into the grinding chamber for grinding by vibrating feeder equably and continuously. The powder after grinding goes upwards together with the airflow, after separating by powder separator, those which can meet the fineness requirement enters into the cyclone powder collector through pipe together with the airflow, and then discharged from the discharge valve as final products. The airflow is sucked into centrifugal blower through wind recycling pipe at the upper part of cyclone powder collector.

The grinded material in the grinding room may contain moisture to some extent, the heat generated during grinding makes the moisture evaporated and changes the air current, and since the pipeline joints are not airtight, the external air is sucked in and the circulation air increases. Thus the balance of the air current can be achieved through adjusting air pipe which is between the air blower and the main engine. The superfluous air current will be led into the bag dust catcher; the fine powder that is along with the air current will be collected. And the superfluous air current will be discharged after being purified.

1. High efficiency, operability;

2. Applicable viscosity: 20000cps the following;

3. Large-volume solid-liquid biphasic suspension;

4. Imported cartridge-type double-ended mechanical seal, the safety is better than other rod-type sander;

5. Cavity and bar pin with high wear-resistant alloy, no loss, no rust, grinding chamber volume can be adjusted;

6. Grinding materials do not change color, no pollution;

7. Shell, face and spindle with cooling, cooling effect, material temperature can be controlled within 45 ℃ (through 10 ℃ chilled water);

8. Separation screen: a special high wear-resistant material, the sieve gap can be adjusted according to different sizes grinding beads, simple and convenient; and there is a protective device to prevent the card beads;

9. Grinding media fineness optional range 0.3 to 3mm → high efficiency large flux rotor separator system, is 3-5 times the ordinary sand mill nm;

10. Grinding material fineness of up to 1um or so (according to customer technology to adjust)

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.