The Durable Roller Mill is the equipment used for pulverizing brittle materials, suitable for pulverizing clinker, raw materials (limestone, sandstone, etc), gypsum, coal, silica sand, iron ore, blast furnace slag, etc.

The roller mill manufactured by EO has the advantages of compact structure, small size, high productivity, low power consumption, simple operation and maintenance, etc. For the same requirements of capacity in the pulverizing system, the productivity can be increased by 30% to 40% when using roller mill while the power consumption can be reduced by 20%-30%. Compare to other pulverizer, the roller mill has the advantages of lower dust and lower noise level, which can improve the environment at site and reduce the capital investment significantly. The equipment can meet the demand in cement production line under 5000t/d.

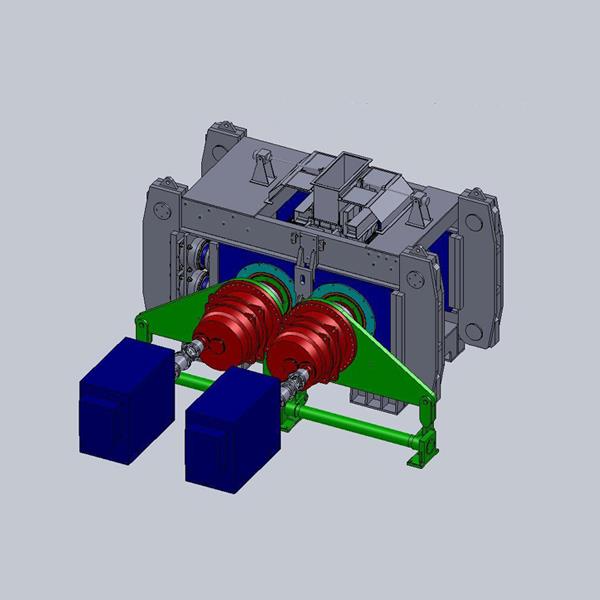

Working Principle of Durable Roller Mill:

Roller mill LHG has the similar working principle to superfine impact mill and jet mill:

1. Feeding and grinding: After the materials are fed into milling chamber, they will be ground into superfine powders by grinding roller.

2. Classification: relatively coarse and fine powders will be separated from each other under the centrifugal force of classification impellers and the draft force of induced draft fans.

3. Collection: Qualified products will be collected and unqualified products will re-enter into milling chamber for second time grinding.

Cleaned air will be discharged by induced draft fans.

Features of Durable Roller Mill:

1. Lower energy consumption for producing the same amount of materials.

2. High fineness: our roller mills are equipped with high precision classification system, which help guarantee high product fineness. And the particle size distribution of finished product is adjustable.

3. This impact mill is suitable for grinding materials with wide range of size: 325mesh-2,500mesh are all possible.

4. Wear-resistance: the wearing parts for our roller mills are made of wear-resistance composite materials, which feature longer service life.

5. Intelligent operation control guarantees a simple operation and stable performance.

6.Environmentally friendly: the main machine adopted vibration-reduction and noise-cancellation

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.