High capacity PC Series Hammer crusher breaks the material through the impact force between the high-speed rotating hammers and materials. It has the advantages of simple structure, large crushing ratio and high production efficiency. It can be used both for dry and wet forms of crushing, and widely used in mining, cement, coal, metallurgy, building materials, roads, fuel and other departments, crushing the medium hardness and brittleness materials. The grate gap of hammer crusher can be adjusted according to user different particle size requirements.

Hammer crusher can be classified into reversible type or irreversible type, wherein the reversible type hammer crusher has reversible rotor and is commonly used for fine crushing; irreversible type hammer crusher has irreversible rotor, and is commonly used for intermediate crushing. The one-stage hammer crusher is irreversible typically.

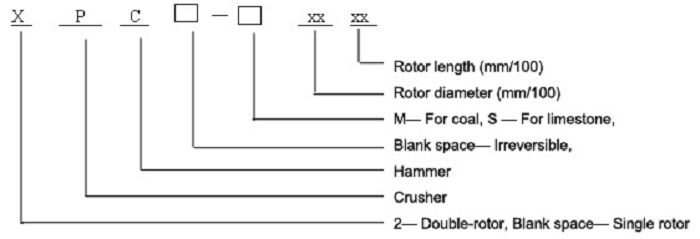

Specifications

Performance Parameter Table of PC Series Hammer crusher

| Specification | Feeding | Discharging | Output | Rotor | Rotor | Rotor |

PCK-1413 | ≤80 | ≤3 | 400 | 1430 | 1300 | 985 |

PCK-1416 | ≤80 | ≤3 | 400 | 1410 | 1608 | 985 |

PCK-1413 | ≤80 | ≤3 | 200 | 1430 | 1300 | 735 |

PCK-M1010 | ≤80 | ≤3 | 100-500 | 1000 | 1000 | 980 |

PCK-M1212 | ≤80 | ≤3 | 150-200 | 1250 | 1250 | 740 |

PCK-M1316 | <300 | 0-10 | 150-200 | 1300 | 1600 | 740 |

PCK-M1818 | <300 | <40 | 500 | 1800 | 1800 | 590 |

PCK-M1825 | <300 | <25 | 700-750 | 1800 | 2500 | 590 |

PC-S0604 | <100 | <35 | 12-15 | 600 | 400 | 1019 |

PC-S0806 | ≤120 | ≤15 | 18-24 | 800 | 600 | 980 |

PC-S0806 | ≤12 | 18-24 | 600 | 1100 | ||

PC-S0806 | ≤15 | 35-45 | 800 | 980 | ||

PC-S1212 | ≤200 | ≤20 | 100 | 1250 | 1250 | 735 |

PC-S1414 | ≤250 | ≤20 | 170 | 1400 | 1400 | 740 |

PC-S1616 | ≤350 | ≤20 | 250 | 1600 | 1600 | 595 |

| Specification | Main motor | Application | |||

Model | Power kW | Speed r/min | Voltage V | ||

PCK-1413 | JS1410-6 | 520 | 985 | 3000 | Crush brittle materials |

PCK-1416 | Y500-6 | 560 | 985 | 6000 | The same as above |

PCK-1413 | JS1410-8 | 370 | 735 | 3000 | The same as above |

PCK-M1010 | JS138-6 | 280 | 980 | 3000 | Coal |

PCK-M1212 | JS148-8 | 310 | 735 | 3000 | The same as above |

PCK-M1316 | JS147-8 | 200 | 740 | 6000 | Coal |

PCK-M1818 | JR1512-10 | 480 | 590 | 6000 | lignite |

PCK-M1825 | YR800-10/1430 | 800 | 590 | 6000/3000 | limestone |

PC-S0604 | Y180L-4 | 22 | 1470 | 380 | limestone |

PC-S0806 | Y280M-6 | 55 | 980 | 380 | limestone |

PC-S0806 | Y280S-4 | 75 | 1480 | limestone | |

PC-S0806 | Y315S-6 | 75 | 990 | limestone | |

PC-S1212 | JS136-8 | 180 | 735 | 380 | limestone |

PC-S1414 | JSQ1410-8 | 280 | 740 | 6000 | limestone |

PC-S1616 | JSQ1512-10 | 480 | 595 | 6000 | limestone |

Remark:

1. Rotor diameter refers to motion curve of top end of hammer head in working state of rotor.

2. Output of coal hammer crusher means that compression strength limit of crushed material of crushed materials is 12MPa, surface moisture is less than 9%, and bulk density is 0.8-1t/m3.

3. Output of limestone hammer crusher means compression strength limit of crushed material of crushed materials is 120MPa, surface moisture is less than 2%, and bulk density is 1.6t/m3.

Performance Parameter Table of One-stage Hammer Crusher

| Specification | Rotor diameter | Rotor length | Maximum feeding | Discharging | Output |

PCY-S2020 | 2000 | 2000 | 1100 | 20/80 | 300-400 |

PCY-S2030 | 2000 | 3000 | 1100 | 20/80 | ≤700 |

| Specification | Main Motor | Feed roller motor | ||||||

Model | Power kW | Speed r/min | Voltage V | Model | Power kW | Speed r/min | Voltage V | |

PCY-S2020 | YR173/34-16 | 630 | 368 | 6000 | Y250M-8 | 30 | 740 | 380 |

PCY-S2030 | YR1000-16/1730 | 1000 | 370 | 3000 | ||||

Working principle of High capacity PC Series Hammer crusher

The main parts of hammer crusher are rollers with hammer, the rollers consists of main shaft, sphere plate, axis roll and hammer.

Motor drives roller in high speed running inner the crushing chamber, the materials be send from top into the crusher, by the striking, impacting, shearing and grinding into power.

At the bottom is a screen plate, it is used to collecting the materials whose size bellow the size of the screen plate, those size is bigger than the screen gap will be regrind by the hammer, finally discharged from the discharging opening.

Features of High capacity PC Series Hammer Crusher

1. High quality chrome hammer, abrasion resistance achieving the advanced level in country;

2. Specially designing tooth impact plate;

3. Adjustable discharge open;

4. Low power consumption unit;

5. Big crushing ratio

6. Very long operation life

7 Simple structure, reliable operation

8. Easy maintenance, low operation cost

9. Good operating safety, lower energy cost

10. High economic efficiency, low cost, fast recovery

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.