Product Name: Ion Casting Machine

Country of origin: China

Condition: New

Ferroalloy casting machine mainly consisted by head driving device, chain device and rear guiding device, now mainly using suspension casting machine of 20m to 45m.

The casting machine is essential equipment widely used in ferroalloy industry. The basic structure includes great wheel assembly, tail wheel assembly, tensioning gear, Conveyor chain, cast iron mold, round trip riding wheel, reducer, variable-frequency and variable-speed motor and other parts.

The casting machine of ferroalloy is last working process of ferroalloy melting, the liquid iron from the submerged arc furnace will be conveyed into casting machine through liquid iron tank car, and it will become final product ingot after cooling. The casting machine is a chain track of inclining 6°-9°, the mold fixed on the rack. The liquid iron ladle will slowly tilt through overhead head crane along with chain track circulation, the liquid iron will flow into mold and then go through circulation water cooling area, it will form ingot when the cooling finished. The chain track operated with different speed as per submerged arc furnace tapping amount, liquid iron temperature and liquid steel ppuring speed, therefore, the ingot mold inside charges full of liquid iron, the chain track operates smoothly, and the variable-frequency driving motor will be selected according to the technical process requirement.

The casting machine of ferroalloy is last working process of ferroalloy melting, the liquid iron from the submerged arc furnace will be conveyed into casting machine through liquid iron tank car, and it will become final product ingot after cooling. The casting machine is a chain track of inclining 6°-9°, the mold fixed on the rack. The liquid iron ladle will slowly tilt through overhead head crane along with chain track circulation, the liquid iron will flow into mold and then go through circulation water cooling area, it will form ingot when the cooling finished. The chain track operated with different speed as per submerged arc furnace tapping amount, liquid iron temperature and liquid steel ppuring speed, therefore, the ingot mold inside charges full of liquid iron, the chain track operates smoothly, and the variable-frequency driving motor will be selected according to the technical process requirement.

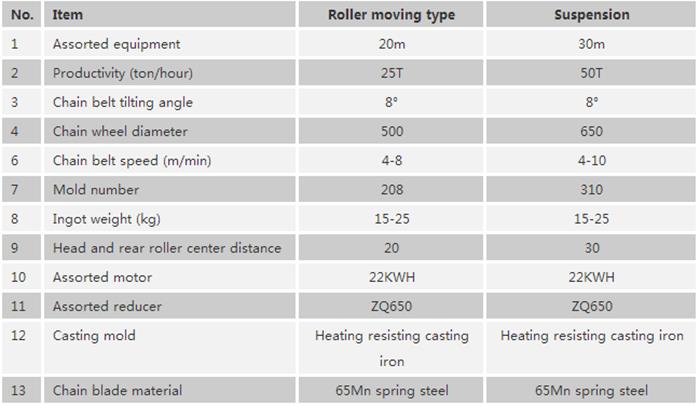

More Details:

As a professional manufacturer and designer of Ion Casting Machine, we can offer various kinds of products with advanced mechanical equipments and experienced technical workers that we can provide this product on top quality and best price. The product will be shipping from China factory directly to your offered address. We are confident to be the best supplier in China.