Brief Introduction of Mining Processing Equipment For Crushed Stone

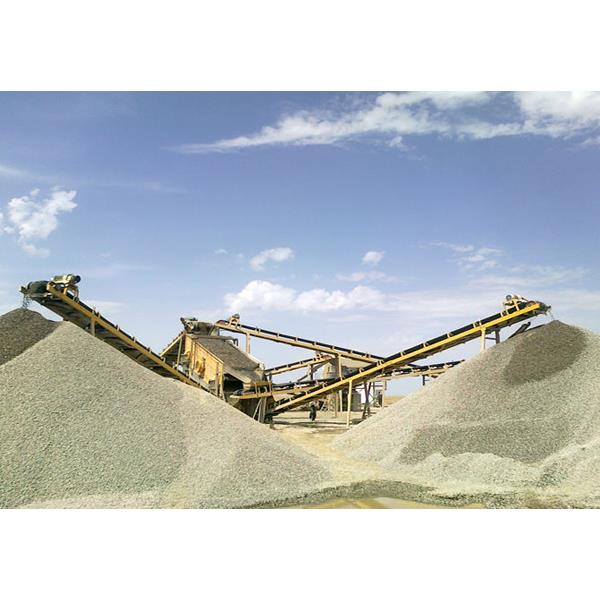

Our company based on the professional production of various kinds of crushing and screening equipment, can undertake single 50t/h-300t/h sand sets of crushing and screening equipment turnkey projects, users only need to provide the terrain conditions and material requirements, product size requirements, requirements of output per hour. Our company can provide users with the process design, equipment, production, installation, commissioning complete until the normal production, our company has more than and 300 users completed the quarry complete crushing and screening equipment engineering contractor service. First class design, first-class products, first-class service has won the majority of customers.

The Structure of the Mining Processing Equipment For Crushed Stone

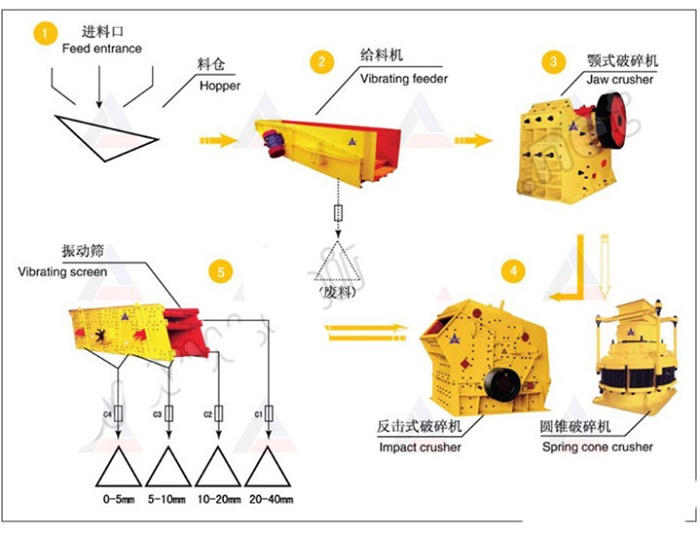

Stone crushing production line generally consists of vibrating feeder, jaw crusher, impactcrusher, vibrating screen, belt conveyor, electric control, etc. We design different production lines ranging 30 t/h to 600 t/h by combining different models of equipment which can match cone crusher, deduster, etc. If necessary to satisfydifferent customers technological requirements. It is widely used for crushing hard limestone, granite, basalt, gravel, metallurgic slag, etc. Or artificialsand making for hydroelectric power, building material, high way, city construction, etc. Different models of machines are combined to meet differentcustomers' different demands according to different craft requirements.

Process of stone crushing Production Line

Big size stones are transferred to primarycrusher through vibrating feeder from hopper for first crushing, then thecrushed materials are transferred to impact crusher through belt conveyor forsecondary crushing. The materials crushed will be transferred to the vibratingscreen, and separated to different sizes. The aggregate with suitable size willbe transferred to the final product pile and aggregate with unsuitable sizewill be transferred to the impact crusher for re-crushing. This forms a closedand manifold cycles. The sizes of final products will be graded and separatedaccording to customers' requirements, and the duster will be attached for thesake of environment protection.

After-sale services

Provide considerate services to minimize clients' worries.

(1) Assist clients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

(4) Examine the equipment regularly;

(5)Take initiative to eliminate the troubles rapidly at site;

(6) Distribute the guarantee fittings door-to-door;

(7)provide perfect service;

(8)Provide technical exchanging;

(9)Provide maintenance for big items.

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.