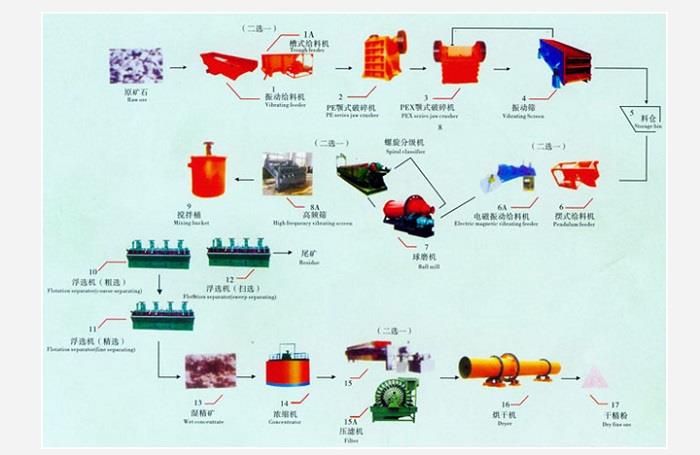

Brief Introduction of Mineral Beneficiation Processing Equipment

Mineral Beneficiation Processing Equipment consists of jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener and dryers and other major components. This Processing Equipment has the advantages of high efficiency, energy saving, high processing capacity and reasonable price.

1.Beneficiation method of the Processing Equipment

1 gravity method

Gravity method is based on the relative density of minerals (usually called the proportion) between sorting mineral. The density of different mineral particles in the moving medium (water, air and heavy liquid) by hydrodynamic and mechanical force, resulting in appropriate loose stratification and separation conditions, so that the mineral particles of different density separation.

2 flotation method

Flotation method is based on the physical and chemical properties of mineral surfaces, the flotation agent treatment, so that the selective attachment of useful minerals on the bubble, to achieve the purpose of sorting.

Beneficiation of non-ferrous metal ores, such as copper, lead, zinc, sulfur, molybdenum mine is mainly used in flotation; some ferrous metals, rare metals and some non-metallic minerals, such as graphite, apatite and the flotation don.

3 magnetic separation method

The magnetic separation method is based on the different magnetic properties of minerals, different minerals in the magnetic field of the magnetic separator is subjected to different forces, so as to get the separation. It is mainly used for the selection of ferrous metal ores (iron, manganese, chromium); also used for non-ferrous and rare metal ore separation.

4.Electric selection method

The electric separation method is based on the difference of the conductivity of minerals. When the mineral passes through the high voltage electric field, the electrostatic force acting on the mineral is different because of the different conductivity of the mineral. Separation of rare metals, nonferrous metals and nonmetallic ores by electric separation. At present, mainly used for the separation and selection of mixed crude concentrate; such as the separation of scheelite and cassiterite; zircon, selection of tantalum niobium ore selection,etc..

2 Complete set of Processing equipment for Beneficiation includes the following parts and their brief introduction

Jaw crusher has the features of high crushing ratio, uniform product size, simple structure, reliable operation, easy maintenance and economic. The jaw crusher is widely used in mining, smelting, building materials, highway, railway, water conservancy and chemical industries for crushing various materials with compression strength less than 320 MPa.

Glass steel rotary spiral chute is a combination of spiral separator, spiral chute, shaker, centrifugal concentrator, the new equipment is the best equipment in the mining, mineral processing, especially coastal, river, beach, Sand Creek Road placer mining is more ideal.

6 - S shaking table is a kind of physical separation equipment. It is mainly used for the separation of gold and silver, zinc, tin, tantalum niobium and other rare metals and precious metal ores. The series combination of domestic table and table gravity separation technology, has the advantages of enrichment ratio, separation efficiency, simple operation, and a the final concentrate and the final tailing. Compared with the traditional process with no chemicals, low energy consumption, convenient management and other advantages, has a high performance price ratio.

The classifier is widely used in mineral processing plant with ball mill with closed loop process of triage process ore sand, or the gravity concentrator to grade ore and fine mud, size classification of ore dressing process and metal, desliming, dehydration and washing operations in.

Don't choose the series flotation machine for ferrous metals, can also be used for non metals such as fluorite and talc.

The magnetic separator is suitable for the wet magnetic separation of magnetite, pyrrhotite, calcined ore, ilmenite and other materials with particle size below 3mm, but also for the iron removal of coal, non-metallic minerals, building materials and other materials

Ball is the material being broken, and then smash the key equipment. It is widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizer, black and non-ferrous metal processing, such as glass ceramics industry production of all kinds of ores and other materials for grinding of dry or wet grinding.

Mining machinery (mining equipment) is a kind of machinery which is directly used for mineral mining and rich selection. Including mining machinery and mineral processing machinery. The working principle and structure of the prospecting machinery are mostly the same or similar to those used in the mining of the same kind of mineral. In addition, a large number of cranes, conveyors, fans and drainage machinery are also used in the mine operation.

According to the ore dressing process can be divided into crushing machinery, grinding machinery, screening machinery, sorting (sorting) machinery and dehydration machinery. According to the principle of separation, the separation machinery is divided into gravity dressing machine, magnetic separator, flotation machine and special mineral processing machinery. Mineral processing machinery is also used in building materials, chemical, glass, ceramics and other industrial sectors.

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.