Ore Grinding Rod Mill is extensively used to pulverize various ores or rocks in the industries of metal and nonmetal mines, water conservancy, building material, etc.

Technical Characteristics

The main body of the rod mill is a low-speed rotary tube horizontally installed on two large bearings. The rod mill is at reduction drive of motor through a reducer or peripheral gearwheels or a low-speed synchronous motor through peripheral gearwheels, while the tube is driven to rotate. The tube is filled with appropriate ore grinding media-steel rods which are lifted to certain height under the effect of eccentric force and friction and fall in throwing or pouring state. The materials to be grinded are continuously fed into the tube from the feed port, and are crushed by the moving ore grinding media, and are discharged outside by overflowing and force of continuous feeding, so as to proceed on next procedure.

Ore Grinding Rod Mill main bearings for the tube diameter of 900-2,100mm are spherical bush bearings, bearings for tube diameter of 2,700mm or above are completely-enclosed 120° self-aligning roller bearings. The bearing is of static structure and is lubricated by high and low-pressure lubrication stations. The sealing of the main bearing with the outside is in the form of piston ring and is excellent by virtue of rubber strips and lubricating greases.

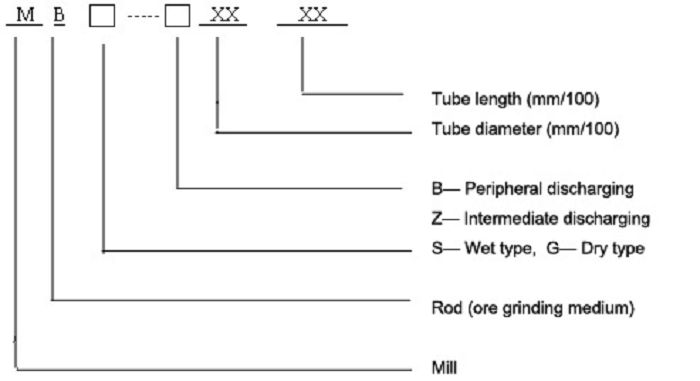

Specifications

Parameter Table of Model Selection

1 Parameter Table of Rod Mill

Specification | Inner diameter | Effective | Working speed | Maximum rod | Main motor |

MBS0918 | 900 | 1800 | 35.4 | 2.5 | 22 |

MBS0924 | 900 | 2400 | 35.4 | 3.55 | 30 |

MBS1530 | 1500 | 3000 | 26 | 8 | 95 |

MBS-Z1530 | 1500 | 3000 | 26 | 13 | 95 |

MBS2130 | 2100 | 3000 | 20.9 | 25 | 210 |

MBS-Z2136 | 2100 | 3600 | 20.9 | 27 | 210 |

MBS2736 | 2700 | 3600 | 18 | 51 | 410 |

MBS2740 | 2700 | 4000 | 18 | 51 | 400 |

MBS-Z2740 | 2700 | 4000 | 18 | 51 | 400 |

MBS3245 | 3200 | 4500 | 16 | 50 | 630 |

MBS3645 | 3600 | 4500 | 14.7 | 110 | 1250 |

MBS3654 | 3600 | 5400 | 15.1 | 124 | 1000 |

MBG-B2130 | 2100 | 3000 | 20.9 | 25 | 210 |

Working principle of Ore Grinding Rod Mill

Asynchronous motor connect with the pinion gear through a speed reducer, direct drive the big gear to rotate thus drive the rotatory part to rotate.The cylinder is equipped with the appropriate grinding medium of steel bar.The material to be grinded is continuously fed into the cylinder by the feeding part. It is crushed by moving grinding medium, and the product is discharged out of the machine by the overflow and the continuous feeding force to carry on the next process.

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.