MZS Autogenous Mill uses crushed medium itself as medium. The effect of mutual impact and grind can crush the material. Autogenous mill is also named non-medium grinding equipment.As the process of grinding is different, there are two kinds of autogenous mills: dry (gas fall) and wet (drop). Now wet type is widely used. As the process of grinding is different, there are two kinds of autogenous mills: dry (gas fall) and wet (drop). Now wet type is widely used.Autogenous mill has two kinds of drag mode: variable speed and constant speed with different power. Some of the autogenous mill has micromotion unit. And the shell is equipped with lifting equipment. Large autogenous mill adopt static pressure bearing to avoid starting static resisting moment and ensure safely operate.

MZS Performance Parameter

| Model | Diameter (mm) | Length (mm) | Feeding (mm) | Discharge | Capacity | Motor | Total (kg) | |||

Model | Power | Speed | Voltage | |||||||

MZ3030 | 3000 | 3000 | ≤300 | ≤50 | 24-30 | YR315M1-4 | 110 | 1484 | 380 | 42390 |

MZS Performance Parameter

| Model | Diameter (mm) | Length (mm) | Feeding Size | Capacity | Motor | Model of Lubrication Station | |||

Model | Power | Speed | Voltage | ||||||

MZS 2409 | 2400 | 900 | ≤250 | According to process | Z2-111 | 55 | 600 | 220 | 16 |

MZS 4014 | 4000 | 1400 | <350 | JR138-8 | 245 | 735 | 380 | 35 | |

MZS 5518 | 5500 | 1800 | <400 | TDMK800-36 | 800 | 167 | 3000/6000 | 50 | |

MZS 7525 | 7500 | 2500 | <400 | TM2500 | 2500 | 375 | 6000 | 100 | |

MZS 7528 | 7500 | 2800 | <400 | TM2500 | 2500 | 375 | 6000 | 100 | |

MZS 6030 | 6000 | 3000 | <400 | TM1250 | 1250 | 428.5 | 6000 | 100 | |

The Weight of Main Part

Specification | MZS 2409 | MZS 4014 | MZS 5518 | MZS 7525 | MZS 7528 | MZS 6030 | |

Weight | |||||||

Total Weight | 27.5 | 63.94 | 159.5 | 454.9 | 463.82 | 230 | |

Weight of Main Part

| Feeding | 0.466 | 1.47 | 2.73 | 4.82 | 4.82 | 3.52 |

Rotation | 15.5 | 43.43 | 110.88 | 258 | 272.78 | 156.8 | |

Bearing | 3.44 | 3.31 | 10.75 | 2.84 | 2.84 | 24.35 | |

Transmission | 2.16 | 8.53 | 22.66 | 92.98 | 92.98 | 27.36 | |

Gearbox | 0.735 | 1.92 |

| 20.4 | 20.76 | 10 | |

Gear | 1.275 | 5.2 | 15.13 | 61.81 | 61.81 | 16.12 | |

Differential Gear |

|

| 7.5 | 30.72 | 30.72 | 8.03 | |

Wheel Device | 0.71 | 2.52 | 5.4 | 27.96 | 27.96 | 9.75 | |

Motor | 1.265 | 2.11 | 14.8 | 22.3 | 22.3 | 12 | |

Maximum WeightV | 2.044 | 7.93 | 26.72 | 21.408 | 28.13 | 21120 | |

MZS Autogenous Mill is the coal crushing and grinding coal machine, it is an important auxiliary equipment of pulverized coal furnace. The grinding process is the process of coal crushing and surface area increasing. In order to increase the surface area, it is necessary to overcome the binding force between the solid molecules, thus consuming energy. Coal is made into pulverized coal in the coal mill, mainly through crushing, crushing and grinding in three ways. Where the crushing process consumes the most energy. The ground energy fee. There are two or more kinds of the above mentioned methods in the process of milling, but the main one is the type of the mill.

Mill type many coal working parts by grinding speed can be divided into three types, namely low speed coal grinding machine, medium speed mill and high speed coal mill.

Low speed coal mill mainly for roller type ball mill, generally referred to as ball mill or ball mill. The utility model relates to a rotating cylindrical or tapered roller. Drum speed of 15 ~ 25 RPM / min. When the ball barrel continues to impact and compression of coal, coal will be made into coal. Then, the coal is dried by the hot air passing through the drum, and the coal powder is sent out. After the separation of the separator, the pulverized coal with a certain particle size is sent into the coal bunker or is directly fed into the pulverized coal burner. Ball mill, bulky high power consumption, large noise; but for coal adapt to a wide range of reliable operation, especially suitable for the grinding of hard coal.

Medium speed mill speed is 50 to 300 rpm, more types of. There is a common plate mill, grinding bowl type and E type mill and roller mill (Figure 2). Their common feature is composed of two parts of the mill grinding group relative motion. The coal was crushed in the two groups of surface milling and grinding and squeezed between. At the same time, the coal mill hot coal drying, and coal grinding area in the upper part of the separator to. After separation, a certain size of pulverized coal with air with pulverized coal grinding, coarse grinding area back grinding. With a compact, small footprint, low electricity consumption of pulverizer (about ball mill from 50 to 75%), low noise, light sensitive operation control and other significant advantages; but the structure and manufacture is complex, the cost is large, and is not suitable for the grinding of hard coal. In large capacity coal fired boiler bowl type pulverizer is used more.

The speed of high speed coal mill is 500 ~ 1500 rpm, which is composed of high speed rotor and shell. Common fan mill and hammer mill. In fan mill (Figure 3) in coal by high speed impact rotor and the mill shell collision, crushed coal and impact each other. The coal mill and pulverized coal separator to form a whole, has the advantages of simple structure, compact structure, initial investment, especially suitable for the grinding of High Moisture Lignite and high volatile and MT tube mill use and working principle.

Ball mill is the key equipment for crushing material after crushing. The ball mill is widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizer, black and non-ferrous metal processing, such as glass ceramics industry production of all kinds of ores and other materials may be grinding of dry or wet grinding.

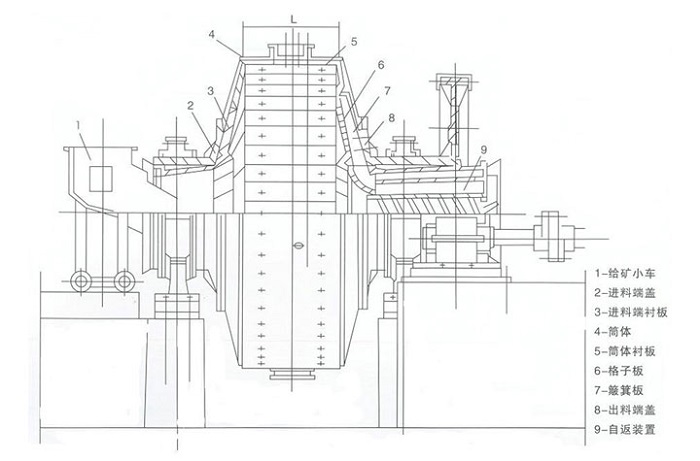

This machine is a horizontal rotating device, outer gear, two warehouses, lattice type ball mill. Material from the feed devicefeedair evenly into the mill screw shaft first warehouse, the warehouse has stepped lining board or corrugated liner, built in different specifications of steel tube to rotate the ball to a certain height, the centrifugal force generated after the fall, pounding and abrasivematerials. After the material is in the first position to be ground, the second compartment is inserted through the single layer partition board, and a flat lining plate is inlaid in the warehouse. Powdered thedischargegratedischarge, finish grinding operation.

The drum type coal mill consists of a feeding part, a discharging part, a rotary part, a transmission part (a reducer, a small transmission gear, a motor, an electric control) and the like. The hollow shaft is made of steel castings, the liner is detachable, rotary gear hobbing with casting, shell lining with wear-resistant, has good abrasion resistance. The machine runs smoothly and reliably.

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.