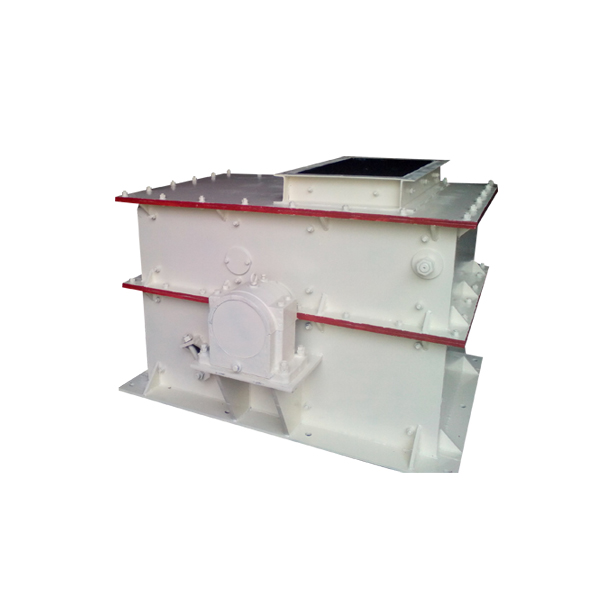

PHZ ring hammer crusher can be used in thermal power plant, metallurgy, mining, chemical and other industries, which crush the raw coal, limestone medium hardness brittle materials. Then the crushing material is squeezed between the ring hammer and the broken plate, through the pressure, shearing and grinding action, make the material reach the required size while material self under the flow, continuous crushing. Iron, wood and other thing is by the ring hammer to dial into the iron room.

The shell is equipped with hydraulic opening, equipment maintenance safety, convenient, large production capacity, small power consumption, low noise, less dust, with digital display monitor supporting spindle vibration and bearing temperature value, can effectively remove the iron, wood and other debris, long life.

Compared with hammer crusher and impact crusher, ring hammer crusher has advantages of high efficiency, energy conservation, stable operation and low noise, and is extensively used in coal pulverization operation of thermal power plants.

Ring hammer crusher is mainly composed of a rack body, a rotor part, a grate part, a synchronous control device, an upper cover hydraulic opening device and other parts. The main machine is connected with a fluid coupling and a motor, and is directly started.

The installation of machine is at right or left, and the discrimination method is that the installation of front motor facing the machine at right part means installation at right; by contrast, it means installation at left.

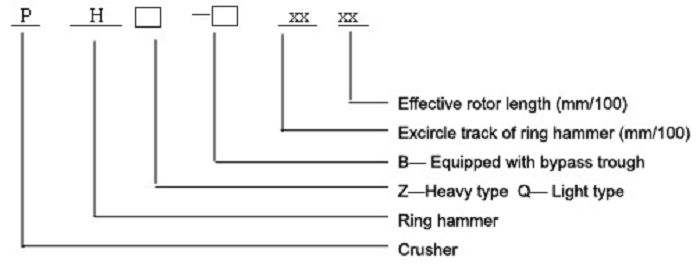

Specifications

Technical Parameter of PHZ ring hammer crusher

| Specification | Roller | Roller | Maximum feeding | Main motor | Discharging | Output |

PHQ-B1111 | 1100 | 1180 | ≤300 | 250 | ≤20 | 400 |

PHQ-B1116 | 1100 | 1676 | ≤300 | 280 | ≤20 | 600 |

PHQ-B1220 | 1226 | 2050 | ≤300 | 450 | ≤20 | 800 |

PHQ-B1226 | 1226 | 2600 | ≤300 | 560 | ≤20 | 1000 |

PHQ-B1228 | 1226 | 2882 | ≤300 | 630 | ≤20 | 1200 |

PHZ-B1213 | 1200 | 1388 | ≤300 | 280 | ≤20 | 400 |

PHZ-B1218 | 1200 | 1804 | ≤300 | 315 | ≤20 | 600 |

PHZ1322 | 1370 | 2200 | ≤400 | 400 | ≤25 | 800 |

PHZ1326 | 1370 | 2680 | ≤400 | 450 | ≤25 | 1000 |

PHZ1331 | 1370 | 3160 | ≤400 | 560 | ≤25 | 1200 |

Working Principle of the PHZ ring hammer crusher:

Ring hammer crusher main working parts with a hammer (also known as the hammer) of the rotor. Rotor from the spindle, disk, pin and hammer. Motor drives the rotor rotating at high speed in the crushing cavity. Material from the upper mouth to feed into the machine, by the high velocity of the hammer blow, impact, shear, abrasive and grinding. The lower part of the rotor, with sieve, mesh size is less than crushing the grain discharged through the sieve, sieve size larger than the coarse sieve retention continue to be a hammer blow and grinding, and finally through the sieve from the plane.

Features of PHZ ring hammer crusher:

1.Can crush the dry or wet materials.

2. Crush the mid-hard and low-abrasive materials;

3. Simple structure, large crushing ratio

4. High production efficiency

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.