PYT cone crusher is one of main machine for intermediate crushing and fine crushing of various ores or rocks in the industries of metallurgy, chemical industry, building materials, hydropower, and road construction, and features reliable structure, stable operation, convenient regulation and high production efficiency. When the crusher works, the motors rotates and drives the eccentric bushing through the coupling or belt pulley, drive shaft and cone gears, and the crushing cone part is forced by the eccentric bushing to rotate and swing around a fixed point, which enables the crushing walls of the crushing cone to be close to or away from surface of crushing wall fixed on the regulation sleeve or upper bracket and crush the ores in the crushing cavity under continuous impact, squeezing and bending effects, and crushed ores are discharged into the crushing cavity depending on its gravity. When some foreign matters unable to be crushed pass through the crushing cavity or the machine is overload for some reasons, springs or a hydraulic safety system can protect the machine and enlarge the ore discharge port. After the foreign matters are discharged from the crushing cavity, the ore discharge port automatically restores under the effect of spring, and then the machine restores work.

Specifications

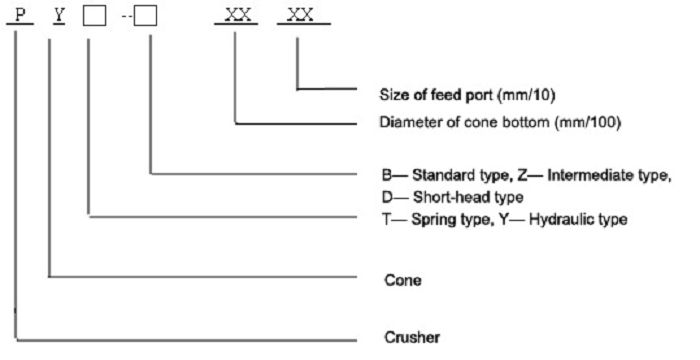

Performance Parameter Table of PYT Cone Crusher

| Specification | Diameter of | Size of | Maximum | Speed of | Regulation range | Output |

PYT-B0607 | 600 | 75 | 65 | 355 | 12-25 | 40 |

PYT-D0604 | 40 | 36 | 3-13 | 12-23 | ||

PYT-B0913 | 900 | 135 | 115 | 333 | 15-50 | 50-90 |

PYT--Z0907 | 70 | 60 | 5-20 | 20-65 | ||

PYT-D0905 | 50 | 40 | 3-13 | 15-50 | ||

PYT-B1217 | 1200 | 170 | 145 | 300 | 20-50 | 110-168 |

PYT--Z1211 | 115 | 100 | 8-25 | 42-135 | ||

PYT-D1206 | 60 | 50 | 3-15 | 18-105 | ||

PYT-B1725 | 1750 | 250 | 215 | 245 | 25-60 | 280-430 |

PYT--Z1721 | 215 | 185 | 10-30 | 115-320 | ||

PYT-D1710 | 100 | 85 | 5-15 | 75-230 | ||

PYT-B2235 | 2200 | 350 | 300 | 220 | 30-60 | 590-1000 |

PYT--Z2227 | 275 | 230 | 10-30 | 200-580 | ||

PYT-D2213 | 130 | 100 | 5-15 | 120-340 | ||

600 ultrafine gyradisc | 600 | 20-30 | <20-30 | 355 | 3-13 | 10-20 |

Performance Parameter Table of PYT Cone Crusher

| Specification | Motor | Sets of | Total pressure of springs | Specification of | Consumption of | |||

Model | Power kW | Speed r/min | Voltage V | |||||

PYT-B0607 | Y250M-8 | 30 | 730 | 380 | 8 | 400/50 | 16 | 1.2 |

PYT-D0604 | ||||||||

PYT-B0913 | Y315S-8/4135T-1 | 55/80 HR | 720/1500 | 380 | 10 | 700/70 | 16 | 1.2 |

PYT--Z0907 | ||||||||

PYT-D0905 | ||||||||

PYT-B1217 | | 110 | 735 | 220/380 | 10 | 1500/150 | 63 | 3 |

PYT--Z1211 | ||||||||

PYT-D1206 | ||||||||

PYT-B1725 | JS128-8 | 155 | 735 | 220/380 | 12 | 3000/250 | 125 | 6 |

PYT--Z1721 | ||||||||

PYT-D1710 | ||||||||

PYT-B2235 | JSQ1510-12/ | 280/260 | 490/485 | 6000/3000 | 16 | 4000/250 | 125 | 6 |

PYT--Z2227 | ||||||||

PYT-D2213 | ||||||||

600 ultrafine gyradisc | Z2-102 | 40 | 600-1200 | 220 | 8 | 400 | 16 | 1.2 |

Brief description about PYT cone crusher

Cone crusher is suitable to crush various kinds of ores and rocks of medium or above medium hardness, and cone crusher is of stable structure, high efficiency, easy adjustment, and use economically, etc. The spring safety system of crusher acts as an overloading protection system that allows metals to pass through the crushing chamber so as not to damage the cone crusher. The safety system uses diluted oil and water as two kinds of sealed formation to make plaster powder and engine oil separated . The type of crushing chamber depends upon the size of feeding and fineness of the crushed product. The standard type(PYB) is applied to medium crushing, the medium type is applied to medium or fine crushing and the short head type is applied to fine crushing.

Features Of PYT cone crusher:

1. Laminating crushing.

2. Well-proportioned particle size.

3. Superior crushing capacity.

4. Successive stable operation.

5. High production capacity (2 times than previous crusher)

6. Adoption of straight metallic contact, which make the replacement of active and fixed cone liners more fast and easy.

7. High efficiency revolving input unit make liners wear evenly.

8. Sweeping system keep its interior tidy.

9. Wide angle star jib make the entry of material more smooth.

10. Automatic overload protection system which prevent from interfusion of iron material.

11. Screw bevel gear system with mute operated.

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.