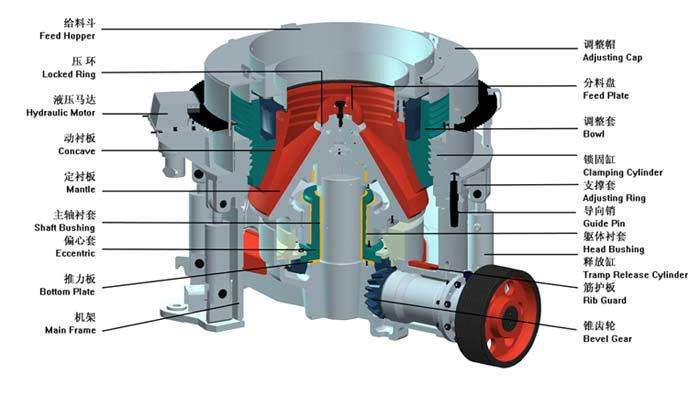

GN high-energy cone crusher, as the latest crusher, has advantage of improving the production capacity of the crusher under the condition of without increasing equipment specification. It adopts more compact, portable and economical crushing equipment than other cone crushers in technological development. Our company designs high-energy cone crusher suitable for crushing hard rocks through the structural update of main components under the premise of no unnecessary equipment weight. The crusher has adjustable crushing granularity from coarseness to fineness, and its production capacity is a grade larger than cone crusher with the same specification.

Non-contact parts in the equipment adopt protective labyrinth seal to prevent dust and pollutant from entering. The product has functions of hydraulic lock and hydraulic adjustment, excess iron release and cavity cleaning. The matched hydraulic system and lubrication system protect safe and normal operation of equipment, and especially hydraulic system can push the cylinder to adjust the size of ore discharge port to control discharging granularity and output, and doesn't need any hoisting equipment or manual method for rotary adjustment.

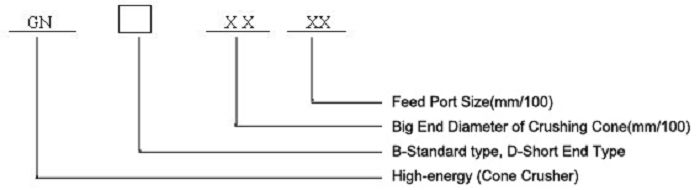

Specifications

Performance Parameter Table 1

| No. | Name | GNB-1021 | GND-1005 | |

1 | Big end diameter of crushing cone mm | 1036 | 1036 | |

2 | Feed port size mm | 215 | 54 | |

3 | Maximum size of feeding block mm | 185 | 45 | |

4 | Ore discharge port adjustment range mm | 25-38 | 6-16 | |

5 | Output t/h | 230-300 | 80-180 | |

6 | Motor | Model | Y355M-4 | |

Power kW | 220 | |||

Rotating speed r/min | 1490 | |||

Voltage V | 380 | |||

7 | Machine weight t | 18.2 | ||

8 | Overall dimensions mm | 2350X2200X2100 | ||

9 | Lubrication station l/min | 125 | ||

10 | Hydraulic oil station MPa | 14 | ||

Performance Parameter Table 2

| Equipment type \Accumulated yield \Granularity | Granularity mm | ||||||||||

Below 25 | Below 20 | Below 14 | Below 10 | Below 6 | Below 2.5 | Below 0.9 | Below 0.56 | Below 0.15 | Below 0.1 | Below 0.074 | |

GND-1005 | 100% | 94.4% | 86.2% | 70% | 51.1% | 32.9%27.2 | 27.2% | 23.5% | 14% | 9.7% | 8.5% |

Performance Parameter Table 2

Equipment type \Production index | Equipment output | Ore discharge port | Discharging |

GND-1005 | 115 | 11 | 25以下 |

Brief description about GN high-energy cone crusher

Cone crusher is suitable to crush various kinds of ores and rocks of medium or above medium hardness, and cone crusher is of stable structure, high efficiency, easy adjustment, and use economically, etc. The spring safety system of crusher acts as an overloading protection system that allows metals to pass through the crushing chamber so as not to damage the cone crusher. The safety system uses diluted oil and water as two kinds of sealed formation to make plaster powder and engine oil separated . The type of crushing chamber depends upon the size of feeding and fineness of the crushed product. The standard type(PYB) is applied to medium crushing, the medium type is applied to medium or fine crushing and the short head type is applied to fine crushing.

Features Of GN high-energy cone crusher:

1. Laminating crushing.

2. Well-proportioned particle size.

3. Superior crushing capacity.

4. Successive stable operation.

5. High production capacity (2 times than previous crusher)

6. Adoption of straight metallic contact, which make the replacement of active and fixed cone liners more fast and easy.

7. High efficiency revolving input unit make liners wear evenly.

8. Sweeping system keep its interior tidy.

9. Wide angle star jib make the entry of material more smooth.

10. Automatic overload protection system which prevent from interfusion of iron material.

11. Screw bevel gear system with mute operated.

Our Services:

Pre-sale services: enthusiasm

We provide you with the process plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the job site for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warranty to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.